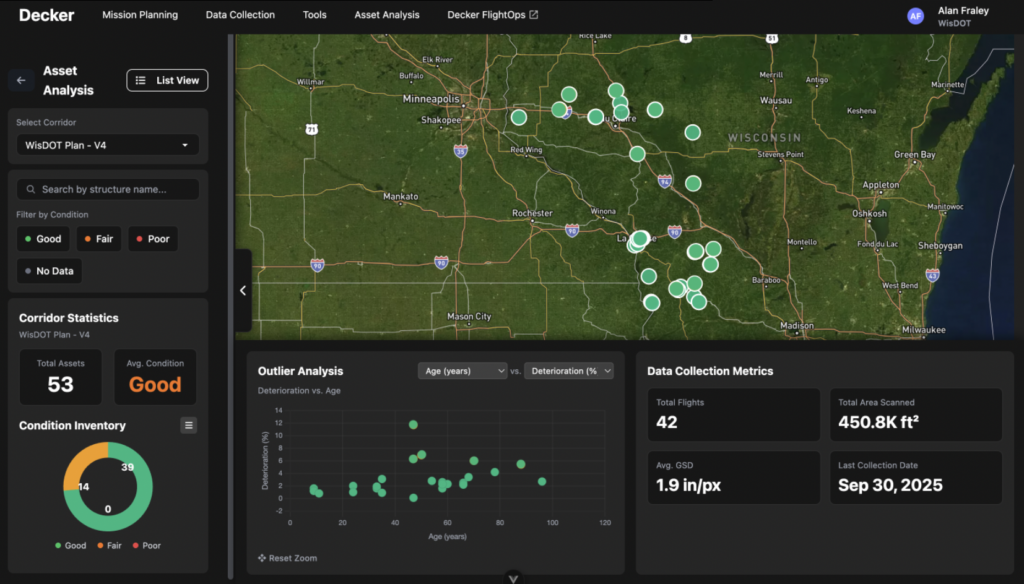

Alynix Decker showcased as part of an internal bridge deck NDE study

The Alynix Decker system, showcased at the 2025 IHEEP Conference, delivered strong correlation with other inspection methods in WisDOT’s ongoing pilot study. WisDOT used Decker to inspect 42 bridges, with AI-driven accuracy, rapid deployment, and an integrated data pipeline proving scalable, efficient, and aligned with traditional verification.

Unlock Smarter Pre-Bid Estimating and Mapping with Alynix’s Decker System

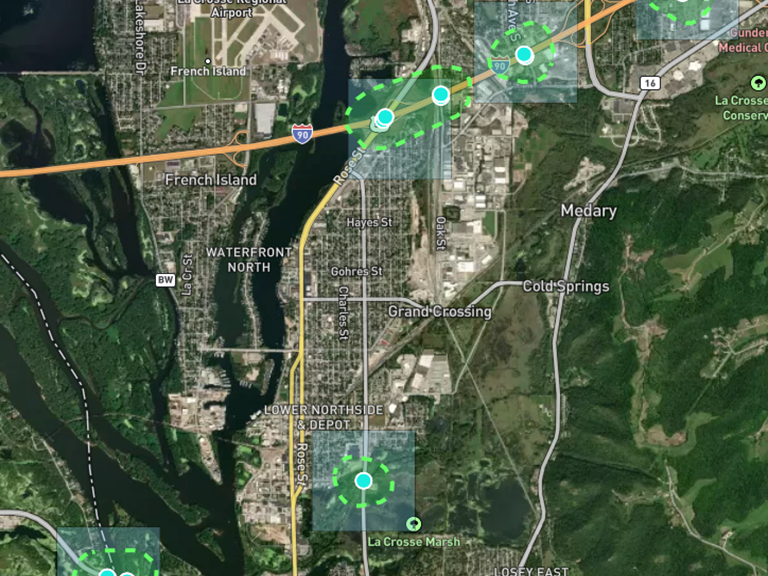

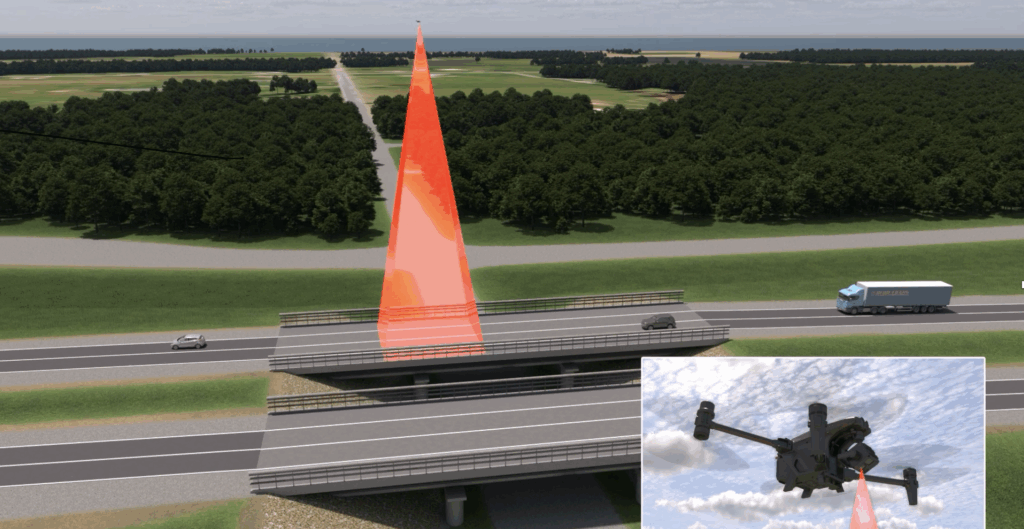

Craft your RFP on data, not guesswork Preparing accurate pre-bid estimates for bridge deck delamination—and visualizing where work is needed—is vital to efficient allocation of resources and safer project execution. Alynix’s Decker system addresses these challenges head on by combining drone-based infrared thermography with AI-driven analytics to deliver reliable inspection data at scale—without traffics disruptions […]

Your Bridge Deck Inspections, Planned and Executed for You – Fast, Simple and Without Lane Closures

Optimization of inspection days and personnel are now built right into your all-inclusive bridge deck inspection system. The Alynix Corridor Planning Tool, part of the Decker Infrared Drone System, allows DOTs, engineering consultants, and infrastructure managers to streamline how they inspect large networks of bridge decks across corridors, districts, counties, or entire state inventories – […]

Maximizing Efficiency in System-Wide Bridge Inspections: Prioritize Deck Repairs, Rehabilitation, and In-Depth Testing

As the summer inspection season kicks off, infrastructure agencies across the nation are tasked with ensuring that the bridges under their care are safe, reliable, and structurally sound. The early stages of this inspection season are crucial for prioritizing repairs, determining when to conduct more in-depth evaluations, and planning essential maintenance. So utilizing tools which enable agencies to quickly and efficiently inspect bridge decks without the need for costly road closures and extensive manual labor is key to making this prioritization happen in a timely manner.

A Smarter Approach to Bridge Deck Inspections

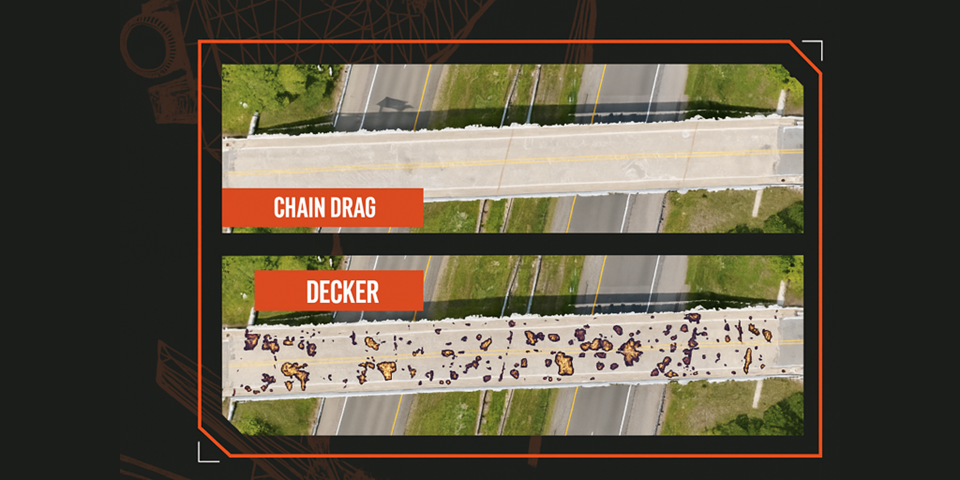

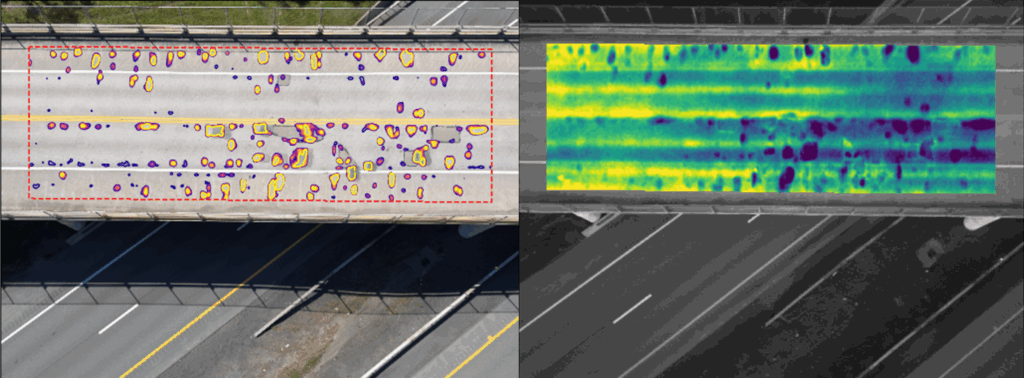

Alynix’s Decker infrared drone system leverages cutting-edge UAS technology to scan bridge decks, infrared thermography to detect subsurface defects, and AI-assisted defect recognition to analyze and prioritize deck repairs. This nondestructive method provides actionable data that can be used to assess the health of concrete bridge decks, helping agencies decide whether a deck requires immediate repairs, further inspection, or is in good condition.

Why Use Decker Drone Systems for Early-Season Inspections?

Speed and Efficiency

Alynix’s system dramatically reduces the time needed for traditional inspection methods. What would normally take days or weeks can now be completed in hours, allowing teams to inspect multiple bridges across districts or even statewide regions in a fraction of the time.

Cost-Effectiveness, No need for MPT

Traditional inspection methods, such as chain drag, GPR, or vehicular-mounted infrared thermography, often require road closures, maintenance and protection of traffic (MPT), and extensive labor, driving up both operational costs and risks. With the Decker drone system, the cost of inspections is significantly reduced—inspection costs as low as $0.03 per square foot—without the need for closures or labor-intensive processes.

Enhanced Data Quality

The infrared scans captured by the drone system allow for a deep analysis of the bridge deck’s condition. Alynix’s advanced AI and machine learning algorithms process these scans, highlighting areas of concern such as delamination and defects beneath the surface. This gives inspectors actionable insights into where repairs should be prioritized. The system also enables manual evaluation of data, for the engineers who want to dive in.

Safety First

Safety is paramount in bridge inspections, especially when crews are working over active traffic. By using drones, Alynix helps ensure that inspectors are kept off dangerous roadways, eliminating the need for traffic control and ensuring the safety of both workers and drivers.

Prioritize Deck Repairs with Decker Drone Insights

As inspections are carried out early in the season, the Decker system can be used to generate clear, infrared 3D maps that highlight problem areas in bridge decks. This makes it easier for engineers to decide which bridges need immediate repairs or rehabs and which can wait. The system also helps prioritize more in-depth inspections where needed, allowing maintenance crews to focus resources on critical repairs before the situation worsens.

The Value of Early Inspection Season Insights

Using the Decker drone system early in the season can provide invaluable insights for the entire year’s inspection strategy. By obtaining accurate, real-time data from the start, agencies can avoid unnecessary delays and costs while ensuring that their bridge networks are safe, reliable, and structurally sound.

Better Bridge Inspection Season Planning with Alynix

Alynix’s Decker drone system is not just a game-changer for the current inspection season—it represents the future of how infrastructure agencies will approach bridge deck inspections. By combining advanced AI, drone technology, and infrared thermography, Alynix is paving the way for more efficient, cost-effective, and safe bridge inspections nationwide.

The Decker system has been used in 8 states already with 3 more coming online shortly. Start using Alynix’s Decker infrared drone system today to revolutionize your bridge inspections, prioritize repairs early, and set the stage for a successful and safe inspection season.

What Are the Real Costs of Inspecting a Bridge Deck? Comparing Chain Drag, GPR/IRT Vehicles, and UAS with Infrared Thermography

When it comes to inspecting bridge decks, the method you choose doesn’t just affect the data quality—it significantly impacts cost, traffic disruption, and worker safety. Let’s break down the economics of three common approaches: conventional chain drag with lane closures, vehicle-mounted Ground Penetrating Radar (GPR) and Infrared Thermography (IRT) with rolling closures, and the new kid on the block—Unmanned Aerial Systems (UAS) using Infrared Thermography.

Baseline Assumption

An average bridge deck size of 17,000 sq ft is used as our basis for comparison.

MPT averages $10,000 per bridge deck of average sq ft.

Rolling closure MPT averages $4000 per bridge deck of average sq ft.

Shape

1. Chain Drag with Full or Partial Lane Closures1,2

Inspection Speed: ~6,000 sq ft per day (about 3 days per bridge)

Labor & Equipment Cost: ~$2,000/day

Maintenance and Protection of Traffic (MPT): $8,000–$12,000 total (flaggers, signs, lane closures)

Total Cost Estimate:

$6,000 (labor/equipment over 3 days)

$10,000 (avg. MPT)

Total: $16,000 per bridge

Cost per square foot: ~$0.94

Shape

2. Vehicle-Mounted GPR and/or IRT with Rolling Closures2,3

Inspection Speed: ~17,000 sq ft per day (1 bridge/day)

Labor & Equipment Cost: ~$3,500/day

MPT (rolling closures): ~$3,000–$5,000 (escorts, traffic control)

Total Cost Estimate:

$3,500 (labor/equipment)

$4,000 (avg. MPT)

Total: $7,500 per bridge

Cost per square foot: ~$0.44

Shape

3. UAS with Infrared Thermography

Inspection Speed: 3 bridges per day (~51,000 sq ft/day)

Monthly System Lease: $6,000 → $300/day (based on 20 working days/month)

Labor Cost: ~$1,200/day for a two-person crew

MPT: None required

Total Daily Operating Cost:

$300 (system) + $1,200 (labor) = $1,500/day

Per bridge: $500

Cost per square foot: ~$0.03

Shape

The Bottom Line: Cost per Square Foot Comparison

Method

Total Cost/Bridge

Cost per Sq Ft

MPT Required

Workers on Bridge?

Chain Drag

$16,000

$0.94

Yes

Yes

GPR/IRT Vehicle

$7,500

$0.44

Yes (rolling)

Yes

UAS with Infrared Thermography

$500

$0.03

No

No

Shape

Conclusion: A Safer, Cheaper Future

UAS-based inspections using infrared thermography are rapidly proving their value—not only in cost savings but also in safety and efficiency. With zero lane closures, minimal disruption, and a cost per square foot that’s 30x less than chain drag, it’s a method that deserves a closer look—especially when you’re managing large inspection programs with limited budgets and potentially limited inspection seasons due to extreme weather.