The Alynix Decker system was recently showcased at the 2025 IHEEP Conference in Myrtle Beach. In one of the conference’s presentations, the Wisconsin Department of Transportation (WisDOT) presented Thermal Scanning of Bridge Decks. This pilot study is still in progress, but WisDOT shared preliminary findings showing a strong correlation between the Alynix Decker system and other inspection methods.

In summer 2025, WisDOT contracted with Alynix to use their system as the department considers innovative tools and technologies to evaluate structures across Wisconsin.

From 40 Years of Thermography to the Next Leap Forward

WisDOT has been a pioneer in using infrared thermography for over four decades. From handheld and vehicle-based sensors to fixed-wing aerial systems, WisDOT’s Bureau of Structures has explored and tested many methods to improve the speed, safety, and accuracy of deck-level data.

However, as WisDOT’s Chief UAS Pilot Steven Doocy explained during his presentation, the department requires a solution that can economically scale thermographic collection while maintaining precision, a capability that Alynix Decker delivered.

“We all know about drone docks,” said Doocy. “But Alynix took it one step further to put the dock on a trailer and make it mobile.”

The Decker trailer, equipped with its own generator, power station, and Starlink connection, can be deployed and ready for flight in as little as 15–30 minutes, transforming how field teams operate.

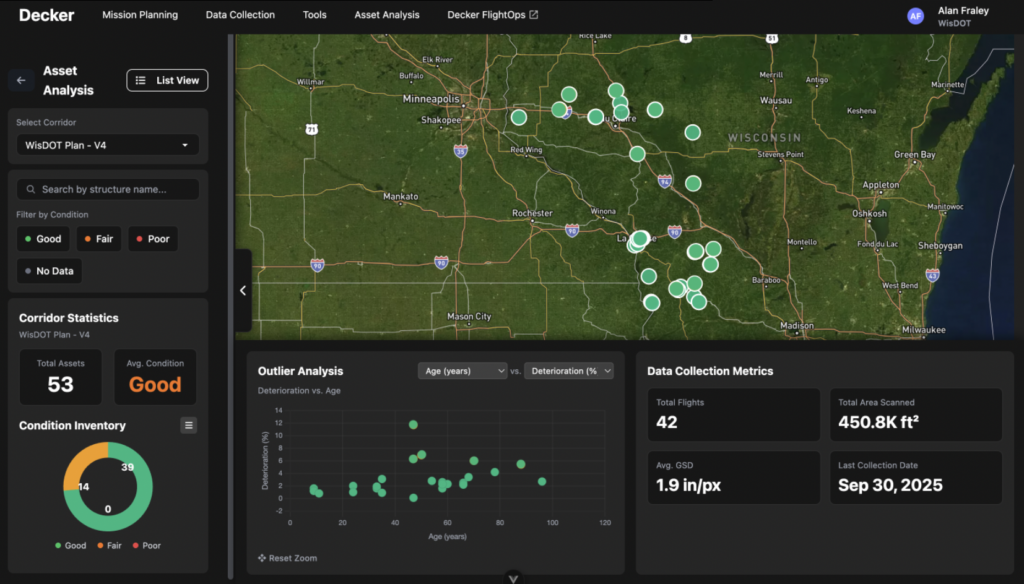

42 Bridges, One Automated Platform

In the first phase of the pilot study, WisDOT utilized the Alynix Decker system to inspect and analyze 42 bridges. The results are now being compared against those from multiple methods: handheld, vehicle-mounted, aerial, and in-house UAS thermography. The final results of the pilot study should be available in summer 2026.

Using Decker’s mission-planning software, the WisDOT team was able to:

- Automatically identify bridge clusters within range,

- Schedule efficient multi-bridge flight sequences,

- Maintain line-of-sight while optimizing flight order and side selection,

- Collect both thermal and RGB data for composite mapping.

Doocy noted that once the flights were complete, Alynix processed and delivered results within days, giving a clear, actionable view of deck conditions and defect grades.

AI-Driven Accuracy in Action

In preliminary comparisons of the Alynix results with other inspection methods, the study found strong agreement between Decker’s AI analysis and field-verified defects, particularly on decks with measurable delamination and surface distress.

“The technology used to process the thermal data matters,” Doocy said. “AI trained to look at pixel data and minute temperature differentials provides consistency and removes much of the subjectivity from inspection.”

The presentation highlighted that Alynix’s STENN-based thermal AI identified subtle variations that can easily be overlooked in manual reviews or standard IR imagery, thereby supporting WisDOT’s broader asset management initiatives.

Efficiency and Value at Scale

Decker’s performance didn’t just show technical merit; it demonstrated sufficient efficiency and cost advantages.

WisDOT compared cost per square foot across various methods, citing Alynix’s published benchmarks as a reference standard for cost realism. Grouping bridges within the same flight mission significantly improves cost efficiency.

The ability to inspect multiple bridges autonomously in a single deployment gives DOTs a scalable model for statewide monitoring programs.

Key Takeaways from the Pilot Study:

- Mobility and Autonomy: The Decker’s trailer-mounted dock enabled rapid deployment without the need for specialized infrastructure.

- AI Precision: Advanced analytics identified delaminations with greater consistency across diverse deck conditions.

- Integrated Data Pipeline: From collection to processed deliverables (PDF, RGB ortho, shapefiles), Alynix streamlined workflow.

- Real-World Validation: Decker’s preliminary results aligned with traditional verification, confirming real-world accuracy.

- Scalability: The ability to capture day-long thermal cycles made Decker uniquely suited for automated, repeatable inspection campaigns.

Paving the Way for Smarter Infrastructure Monitoring

The pilot study proves that automation and AI aren’t just future concepts; they’re here, measurable, and delivering value today.

As transportation agencies seek faster, safer, and more data-driven methods to manage aging infrastructure, Alynix Decker stands as a validated solution that bridges the gap between research and real-world deployment.

About Alynix

Alynix builds autonomous inspection solutions that combine advanced robotics and spatial-temporal neural networks (STENN3) to transform how infrastructure is monitored. From bridge decks to power assets, our Decker platform automates the collection, processing, and interpretation of complex geospatial data, enabling agencies to make smarter decisions faster.